IF RESEARCH BY

Deloitte and Curtin

University proves successful, the latest

generation virtual reality immersion

technologies could soon transform safety

and training in the resource industry.

“It’s about making someone

accountable for their actions and making

them experience something that is not

allowed on a mine site – failure,” says

Coert Du Plessis, Deloitte WA’s advanced

analytics lead partner.

Having undertaken extensive research

into the link between training and safety

outcomes, Du Plessis believes that too

often training is done for compliance

purposes and doesn’t always translate to

positive safety outcomes.

He says utilising new immersive

technologies, such as the Oculus Rift VR

headset, can provide a real-life experience

in different safety scenarios, giving users

a full range of vision and the ability to

physically move and interact within a

virtual environment.

This particular virtual technology was

originally developed for the computer

gaming world, but is quickly going

mainstream. Electronics company Samsung

has reportedly partnered with Oculus to

develop a smart phone with curved sides

that converts into a virtual reality headset.

“Oculus Rift is one example where

someone can be fully immersed in an

environment such as a mine site or a

workshop. We can then present them with

a number of incidents and measure their

behaviour,” Du Plessis says.

“From our experiments, we know

people have a much more emotional

training experience. They can experience

what would happen if they fell from that

platform, didn’t see that electrical fault or

look hard enough over their shoulder when

operating machinery. It’s a virtual failure,

but it has a stickiness and lasting effect.”

VIRTUALLY IMMERSED

in safety training

Standardised training in the resource industry could one day involve an electric shock, falling

off a ledge or crashing a heavy vehicle. Good news is, it will all take place in the virtual world.

Immersive technologies are already

used for training purposes in the resource

industry to an extent, most commonly for

machinery simulators. However, Deloitte

and Curtin University’s research promises

to take it to the next level.

While still in the experimental stage,

Du Plessis is eager to undertake further

trials and help resource organisations

understand the potential to personalise

training, identify gaps in individual learning

and reap cost and productivity benefits.

“There is a lot of data generated in

each experience. We have the ability to

identify, for example, that 80 per cent

of a group had a really great learning

experience, but 20 per cent of the group

didn’t. You can then manage that through

additional one-on-one training,” he says.

The research is funded by the federal

government as part of Curtin University’s

‘Learning for Tomorrow’ strategy and aims

to create authentic environments where

students can apply the theory they learn in

class to industry.

But Du Plessis sees far reaching

potential for the resource industry.

“You can have these immersive

environments shared by more than one

person. For instance, at a FIFO family

day, children can put the headset on

and go with dad on a truck or walk into

the mine and experience what the work

environment is like,” he says.

“It enables families to have a meaningful

conversation about work and safety.

“There is also potential to use it in

the recruitment and induction process

by allowing people to feel what it is

like onsite with the noise and buzz of

everything, before they begin work.”

RP

Coert Du Plessis

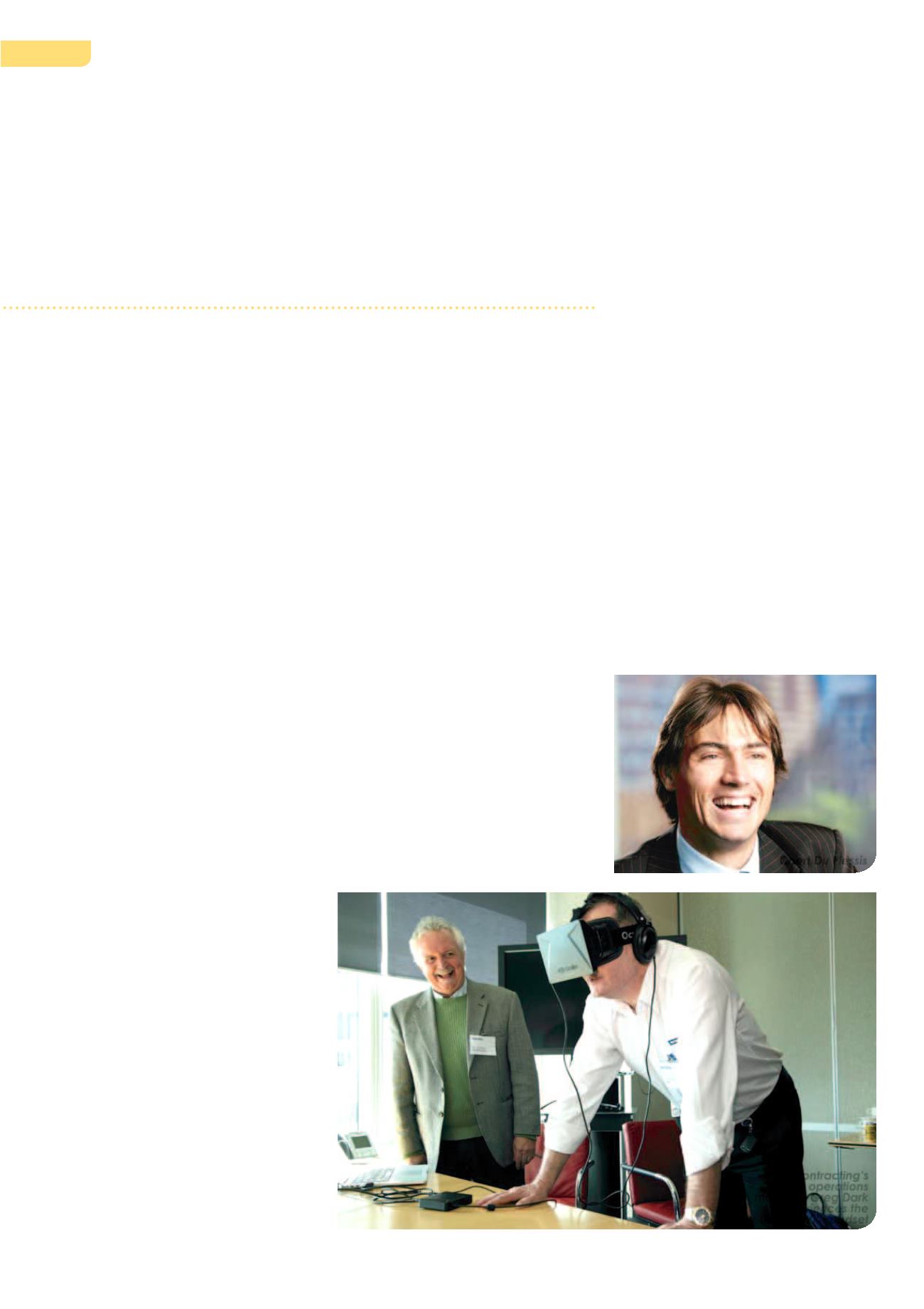

BGC Contracting’s

mining operations

manager Greg Dark

experiences the

Oculus Rift VR headset

SUMMER 2014-15 RESOURCE

PEOPLE

|

|

INNOVATION

46